The HPE III is the most advanced digital durometer hardness tester found in the market today. Not only is it recognized for its accuracy and reproducibility, but during the hardness measuring, the HPE III also registers humidity, environmental and sample temperature, as well as the date and time. With the handheld hardness tester, you can effortlessly measure shore hardness levels on flexible materials, polymers, and composite materials.

Model No: |

FZT-BR/HPEII-1007 | ||

|---|---|---|---|

Brand |

Bareiss | ||

| Applications: | you can measure shore hardness levels on flexible materials, polymers, and composite materials. Its sophisticated functions ensure a correct measuring process, offering protection against operating errors. | ||

Industries: |

Rubber | ||

| Materials: | soft rubber, elastomers, natural rubber products, neoprene, casting resin, polyester, soft PVC, leather, pressure rollers, etc | ||

| Standards: |

|

Its sophisticated functions ensure a correct measuring process, offering protection against operating errors. This portable hardness tester has a unique and exclusive design that makes it the most reliable shore durometer on the market. A large LCD display for reading comfort, a USB connection for data transfer, a rechargeable battery, and our patented handgrip for achieving correct measuring angle and amount of force are all standard features on the HPE III digital durometer tester.

Digital Durometers – HPE III Series shore hardness tester can be used with the Bareiss fully automatic or manual test stands to minimize the operator’s influence on the reading.

| Operating Temperature | 0°C to + 55°C |

| Specimen Temperature | 0°C to + 70°C |

| Ingress Protection | IP 50 |

| USB Power Supply | |

|---|---|

| Output | 5 VDC 1000 mA |

| Input | 100- 240 VAC 50/60 Hz 150 mA |

| Communication Interface | |

| Data output | RS232 |

| Charging cable/ communication line | RS232/ USB- Converter |

| Display | |

| Graphic display | 102 * 64 PIXEL |

| Option for sensor ambient temperature & humidity | |

| Temperature range | -20°C to + 80°C |

| Humidity range | 0% to 100% |

Operating Procedure

1) This digital durometer uses a patented handgrip for achieving correct measuring angles and pressure.

2) When the sample is placed on a flat surface and the hardness tester is turned on, use the durometer handgrip to press down and record the shore hardness scale of the measurement.

3) This portable digital durometer shows the date, time of the last measurement, type of measurement & measuring time, ambient temperature, relative humidity, and max value of the last measurement taken.

4) The measurement time begins as soon as the durometer is pressed onto the sample.

5) The pressure is maintained against the sample according to the chosen dwell time and the reading is indicated with the sound of a beep.

6) The measurement is finished as soon as the durometer gauge loses contact with the sample which will be indicated by the sound of a double beep.

Product features and benefits

1) Durability: The casing is made of aluminum alloy which provides robust structure and lightweight handling.

2) Large Display: The durometer gauge has a large display of 102 x 64 pixels consisting of the header for the general data information of (a) Temperature (b) Humidity (c) Date and Time. Also in the display panel are the measurement results on the test sample and navigation bar, plus the charge status of the battery.

3) Optional feature: Sensor to measure ambient temperature and humidity as well as a built-in sensor to record sample temperature if required for a particular shore hardness test.

4) Reliability: HPE III shore durometer has a patented handgrip for achieving the correct measuring angle and amount of force applied.

5) Intuitive User Interface. HPE III is designed for one-handed operation

6) Storage: 300 Historical measurements can be displayed for the hardness values and date/time when each measurement was taken.

7) Connectivity: The shore hardness tester has a serial interface and USB cable which can be connected to the pc to conveniently export in various formats or make any updates on the durometer by using the designated software.

8) Compatibility: HPE III is compatible with all Bareiss test stands. To ensure the most reliable results, the operator can perform a test according to the standard with minimum interference.

We provide Ranges of applications. download the brochure from here

Ranges-of-Applications-and-Technical-Data_FZ_-1 (1)

Application

| Test Method | Range of Application | Standard | Minimum material thickness[mm] | Indenter(mm) |

|---|---|---|---|---|

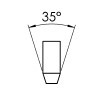

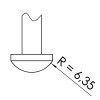

| Shore A | soft rubber, elastomers, natural rubber products, neoprene, casting resin, polyester, soft PVC, leather, pressure rollers, etc. | DIN EN ISO 868 | 4 |  |

| DIN ISO 7619, ASTM D 2240, NFT 51-174, BS903 Part. A 26 | 6 | |||

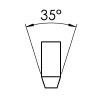

| Shore B | middle hard materials from rubber, typewriter roles, flat materials | ASTM D 2240 | 6 |  |

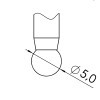

| Shore 0 | soft elastic materials, pressure rolls, middle firm, textile fabrics, nylon, orlon, perlon, rayon | ASTM D 2240 | 6 |  |

| Shore A0 Shore E | Soft foam, leather covers | DIN ISO 7619 ASTM D 2240 | 6 |  |

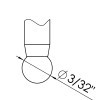

| M Shore A | Shore A | Bareiss Standard | 1.5 | |

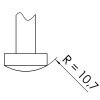

| Shore D | hard rubber, hard plastics, acrylic glass, polystyrene, rigid thermoplastics, Resopal, pressure rollers, Vinyl plates, cellulose- Acetate, etc. | DIN EN ISO 868 | 4 |  |

| DIN ISO 7619, ASTM D 2240, NFT 51-174, BS903 Part. A 26 | 6 | |||

| M Shore D/C/D0 | Shore D 0,5 | Bareiss Standard | 1 | |

| Shore C | plastics and middle hard rubber materials | ASTM D 2240 | 6 |  |

| Shore D0 | plastics and middle hard rubber materials | ASTM D 2240 | 6 |  |

| Shore 00 | sponge- and foam rubber, cellular rubber, silicone | ASTM D 2240 | 6 |  |

| Shore 000 | sponge- and foam rubber, cellular rubber, silicone | ASTM D 2240 | 6 |  |

| Shore 000 S | sponge- and foam rubber, cellular rubber, silicone | ASTM D 2240 | 6 |  |

| Shore AM/M | Shore A | DIN ISO 7619 ASTM D 2240 | 1.5 |  |